what is agc?

There are many different types of power generation sources that make up the generation mix in a modern power system. Most of these sources of generation rely on using energy to rotate a turbine connected to a synchronous machine, although there some are non-rotating sources of generation which do not use turbines and synchronous machines (photo-voltaic cells). The energy used for rotating type generators can come from a variety of places. One approach is the combustion of fuels, like gas, to create heat which can be used to boil water and drive a steam turbine. The heat required to boil the water does not necessarily have to come from combustion and can be derived from a number of sources like nuclear, concentrated solar, or geothermal. Moreover, turbines do not have to be driven by steam. Hydraulic turbines use water from a river or lake - the mass of the flowing water is used to rotate the synchronous machine. Below is an image of a hydraulic turbine attached to a synchronous generator.

The key takeaway here is that rotating generation sources are made up of two key parts: a turbine, and a synchronous machine. The turbine provides the rotation force, and the synchronous machine creates the electrical power. The most common type synchronous machine used for power generation is a three phase machine. The three phase machine produces three sinusoidally varying voltage outputs, which are phase shifted from each other by 120 degrees - the image below explains this relationship more clearly.

The sinusoidally varying nature of the curves is an artifact of the synchronous machine rotation. In fact, the faster the machines are rotated, the higher the frequency of the sinusoidal curves. The relationship between machine rotor angular velocity, , and the output frequency, , is given by the well known formula:

The frequency, , is an important feature of generation since the electrical appliances and motors that are connected to power system distribution networks are designed to operate at designated frequencies. Connection to a network which does not supply the design frequency will cause damage to the appliance or motor. In Australia the agreed frequency of operation is 50Hz. This means that approved electrical appliances and motors are designed to be powered by a 50Hz supply, and more importantly, the Australian power system needs to maintain generation at 50Hz.

Sounds simple right? Just run all the generators so they output power at 50Hz - easy peasy. The trouble starts when we begin connecting load to the network (appliances and motors). What happens is the prime mover, or turbines, apply a mechanical torque to the system, . When we connect load to the system a torque, , is established in opposition to . Letting represents the inertia of the rotating mass, and represents the angular acceleration of the rotating mass then by Newton’s second law the sum of the torques can be expressed as:

If then the system is balanced and does not speed up or slow down; however, if or then there is a non-zero angular acceleration and system speeds up or slows down, respectively.

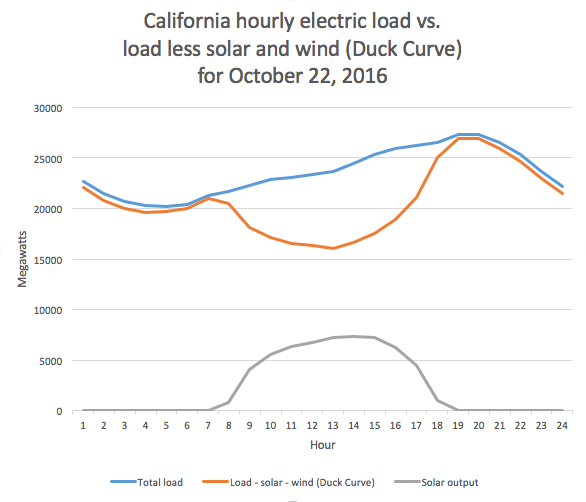

Okay. So that throws a spanner in the works, but why don’t utility providers just work out what load is going to be on the system at each point in time and provide the appropriate mechanical torque to meet this? To some degree that is what happens. Utility providers try to forecast how much power is going to be demanded at each point in time over a 24 hour cycle. They use information like historical demand and weather forecasts to help with their prediction, but it’s not perfect. The reality is that you or I can switch on what ever appliance we like at whatever time we like, and the utility provider has to be able to meet this power demand instantly. The technical terminology for this is a stochastic load profile. An example of a load profile can be seen below. The next day’s load profile will look similar, but not identical to this one.

Inevitably, there will be small imbalances between and which will result in a continually changing system frequency. To maintain the frequency at 50Hz power systems operators, like the Australian Energy Market Operator (AEMO) or the Power and Water Corporation (PWC) in the Northern Territory, use synchronous generators referred to as regulating units. These regulating units are on call to increase the frequency, or decrease the frequency as required. Automatic generation control (AGC) is the control system that is used to adjust the power output of regulating generators.